136 Chucks: A Milestone Project for Actemium Mexico

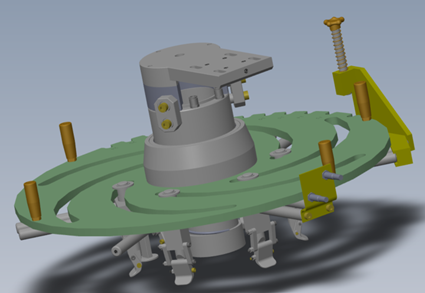

At Actemium Mexico, we continue to demonstrate that world-class engineering can be designed and built right here in Mexico. We recently completed a key project involving 136 automated chuck* mechanisms, designed to transfer automotive wheels from a manual process to an automatic pressing station. These systems operate using compressed air and adjust vertically to grip the wheel based on its rim diameter.

* A chuck is a tool used to firmly hold round objects, like drill bits or workpieces, so they can spin safely and accurately in machines such as drills or lathes.

What made this project special?

Developed under a “Built to Print” design, the project required high-precision machining with tolerances under 0.015 mm and included the creation of a custom test bench capable of validating two chucks simultaneously enhancing both efficiency and ergonomics.

Project stages included:

- Machining of parts

- Mechanical assembly with alignment and adjustment

- Functional testing (FAT) at our Querétaro facility

The project also involved weekly reporting with:

- Completed activities

- Project timeline updates

- Quality and progress evidence (photos, dimensional reports, etc.)

- Change control and FAT documentation

The result?

On-time delivery with zero rework or client complaints. The quality achieved led to a new opportunity: exporting 24 chucks to a plant in Canada. This project was not only a technical success—it was a turning point that strengthened our position as a trusted partner for international industrial solutions.